Lithium battery automated testing equipment

Equipment detection advantages

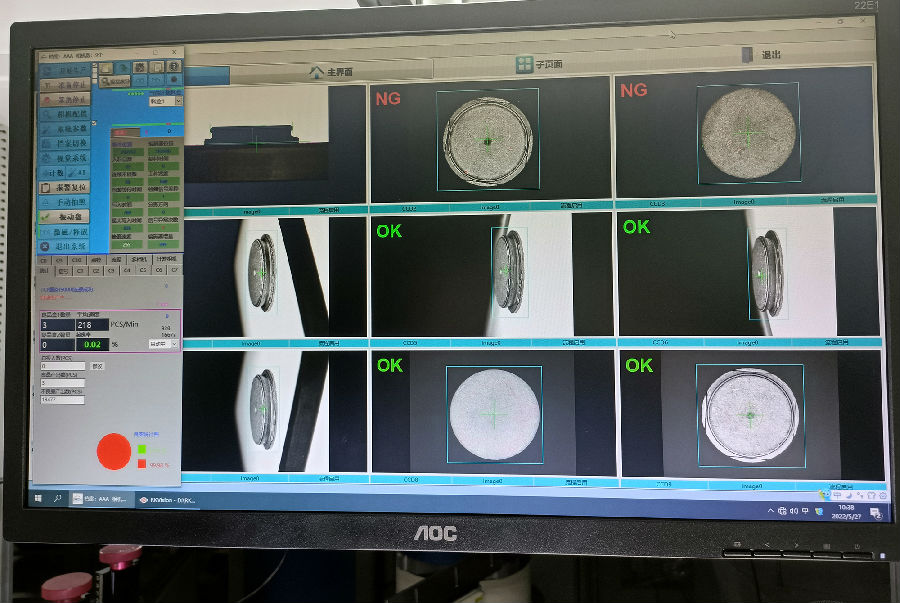

(1) Standardized and data-driven detection results address the impact of subjective intentions, emotions, visual fatigue, and other factors on detection results, resulting in high detection accuracy and stable and reliable detection results;

(2) The detection speed is 600pcs/min, which improves the generation efficiency and can replace the detection of 9 employees, saving labor costs;

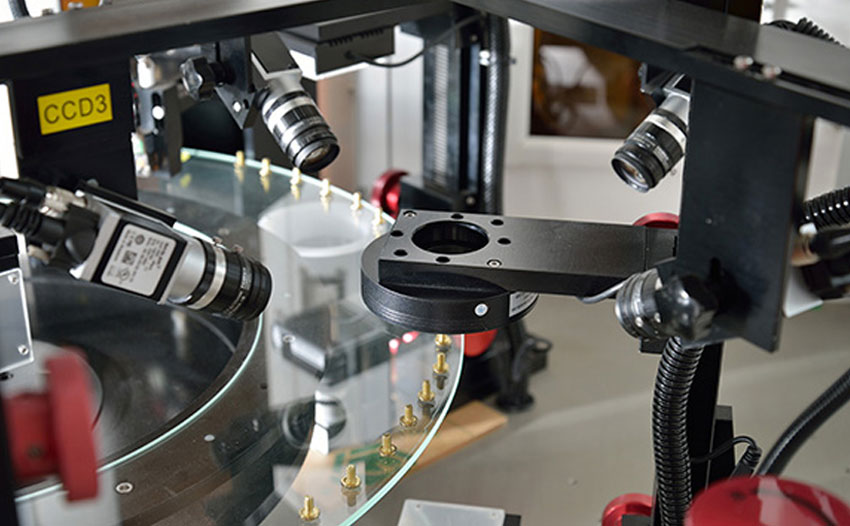

The "lithium battery automated testing equipment" is independently developed by Ruike and used for defect detection in the new energy industry. This device is equipped with 9 high pixel industrial cameras, and the system will transmit stable and clear images of the product to the image processing system. Then, by identifying image features, various defects or size feature information of the lithium battery cover can be analyzed. At the same time, the light source system can monitor brightness based on the images. If there are abnormal products, the system will give abnormal signals, output OK or NG signals, and the blowing valve will automatically classify the products into the corresponding cutting box.

来源声明:本文章系english编辑原创或采编整理,如需转载请注明来自english。以上内容部分(包含图片、文字)来源于网络,如有侵权,请及时与本站联系(400-8560-998)。