What is the development direction of machine vision inspection equipment in automated inspection equipment?

Machine vision has been in China for decades and has made great progress. Now, let's talk about the development direction of machine vision in automated testing equipment in 2020.

There are four main development directions for machine vision: precise positioning, detection, recognition, and measurement.

Accurate positioning

The key is reflected in the application of industrial robots at the level of assembly lines, classification, or transportation work. Industrial robots must visually provide feedback to the intelligent robot's indoor spatial coordinates to show the precise fixed parts and orientations of the parts, ensuring that the intelligent robot can accurately crawl the parts.

detection

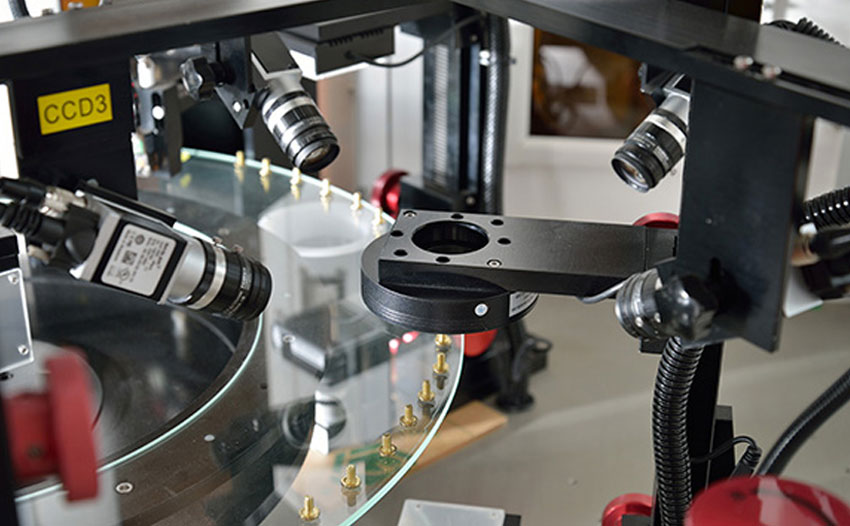

Machine vision is the most widely used stage in automated inspection pipelines to detect product quality issues. In addition, there are also quality inspections of printed items, as well as application stages such as inspection of missing or defective products during the entire process of product assembly. This is one of the directions in machine vision applications.

resolution

Machine vision uses color level discrimination, code reading, autonomous vehicle, texture discrimination and other levels.

measure

The key is to measure the length and perspective in the production and manufacturing of goods. In addition, some products have high accuracy, exceeding 0.01-0.02m or even reaching level u, and human eyes cannot be detected. It is necessary to use machine vision for detection.

Nowadays, machine vision technology in China is widely used in electronic devices and semiconductor equipment, automotive industry, industrial production testing, drug testing, food packaging materials, packaging printing testing, railway and road testing, information security, finance, national defense and other industries. Automated machinery replaces manual labor, and machine vision automated testing equipment will also reach a high point in industrial production and manufacturing applications.

来源声明:本文章系english编辑原创或采编整理,如需转载请注明来自english。以上内容部分(包含图片、文字)来源于网络,如有侵权,请及时与本站联系(400-8560-998)。