What is the working principle of screw optical image screening equipment?

To reduce the complexity of detection operations, the screw screening machine uses photoelectric sensors to determine whether screws have reached the designated position and detect the operation status of the assembly line, ensuring that the main control computer does not need to continuously make failure judgments and can increase the stability of the equipment's work.

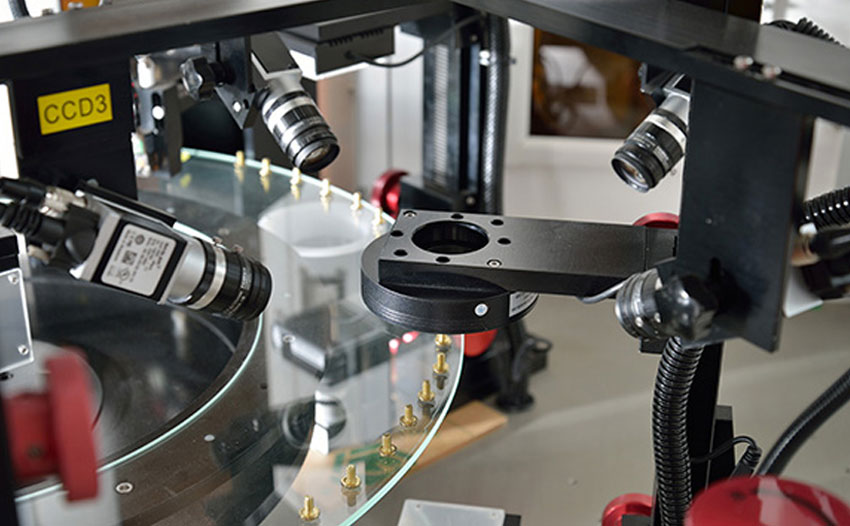

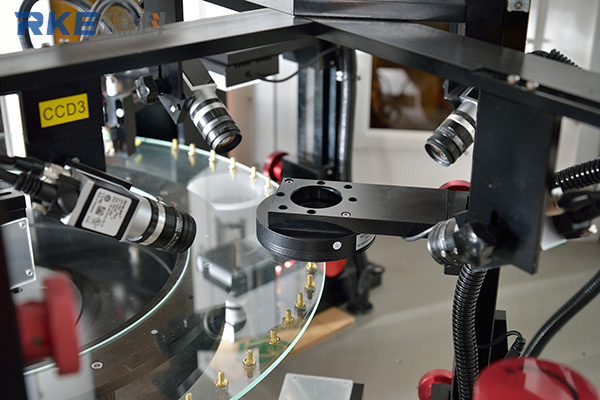

The screw optical image screening machine uses visible light object image acquisition and calculation for real-time parameter detection of screws, which can directly determine whether the screw product is defective or not.

The screw screening machine monitor can directly display screw related images, and the unqualified screws detected through the images can provide signals to directly remove the unqualified products from the assembly line through the mechanical lifting device. At the same time, it can record the number of screws in the shift and the number of unqualified screws.

The above content is an introduction to the working principle of screw screening machines. With the development and upgrading of domestic industry, various precision parts (such as automotive screws and electronic screws) require full inspection of appearance and dimensional quality,? Long term manual visual inspection can lead to eye fatigue, resulting in low efficiency and low accuracy in product testing. Replacing artificial vision with machine vision can significantly improve production efficiency and inspection accuracy, reduce customer complaints, and reduce labor costs.

来源声明:本文章系english编辑原创或采编整理,如需转载请注明来自english。以上内容部分(包含图片、文字)来源于网络,如有侵权,请及时与本站联系(400-8560-998)。