How is hardware inspection detected using visual inspection equipment?

These generally depend on the following aspects:

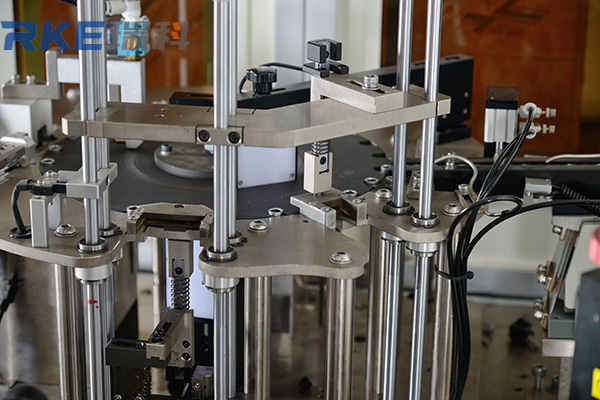

1. The shape of the product is relatively easy to detect surface defects in flat stamped products, while detecting surface defects in non-standard products with strange shapes is definitely a challenge.

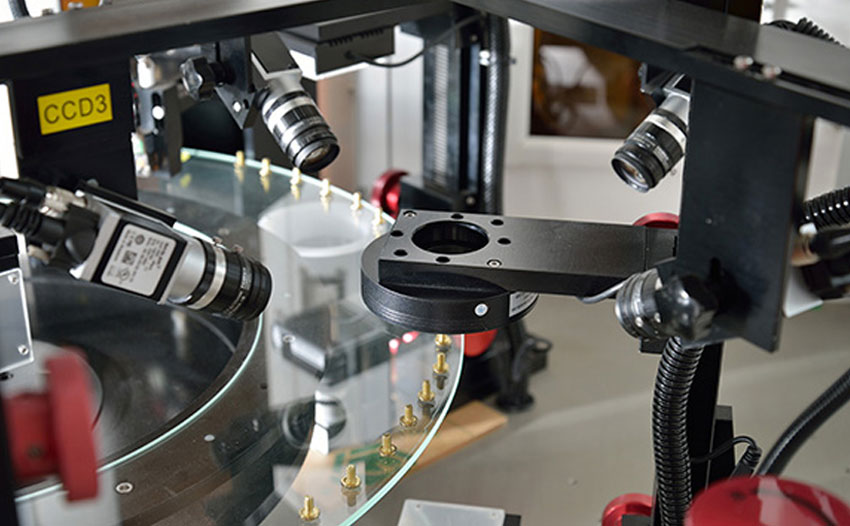

2. The types of defects to be detected are generally not limited to missed processing, surface bumps, pits, scratches, pits, electroplating defects, etc. in hardware products. For missed processing, using a CCD optical screening machine can definitely solve it, as it is a relationship between 0 and 1. If there is, there is, and if there is no, there is no; For defects such as surface bumps and bumps, especially for irregular products, the detection of surface defects is even more difficult. The main reason is that manufacturers themselves are uncertain about the definition of defects. Even if there is a strict definition of defects, it is difficult to use tools to measure the actual size of defects in practice, and basically rely on the naked eye to determine whether they are qualified.

This will make it difficult to meet the customer's needs during the process of using CCD optical screening machines. Either too many defective products are detected, or the detection results cannot meet the customer's needs. Therefore, when purchasing defect detection equipment, customers must have detailed communication with us as much as possible to avoid problems in the future.

来源声明:本文章系english编辑原创或采编整理,如需转载请注明来自english。以上内容部分(包含图片、文字)来源于网络,如有侵权,请及时与本站联系(400-8560-998)。