What are the benefits of CCD machine vision inspection equipment?

On the other hand, although the growth rate of machine vision in China is much higher than the overall automation market in China, the machine vision market in China is still in its early stages, and the demand for industrial automation and intelligence using image and machine vision technology will be widely applied in various industries. According to authoritative industry prediction reports, the market size of China's machine vision industry will continue to steadily grow in the coming years.

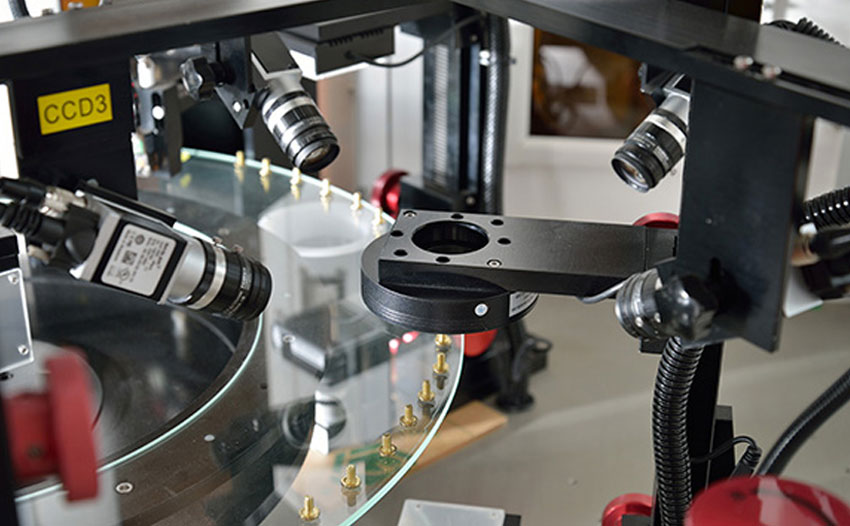

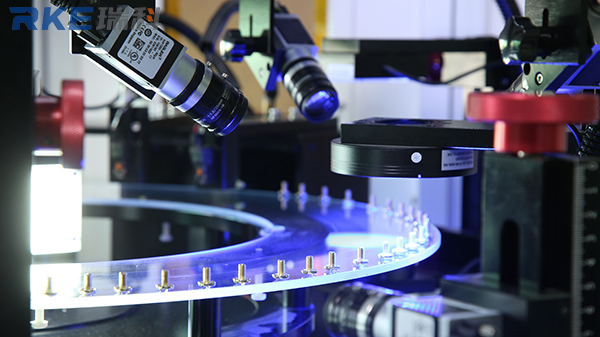

Machine vision systems are divided into four categories:

1. Surface defect detection: This is one of the most commonly used functions in mechanical equipment. It can detect certain information on the surface of the product online, such as scratches, damages, oil and dust, injection molded parts, etc., whether there are blank spaces in white clothing, whether there are errors and omissions in printing, all of which can be judged online through machine vision. Machine vision detection can eliminate defects in the production process of the product, Ensure the stability of product quality.

2. Visual dimension measurement: online automatic measurement of external dimensions, contour, aperture, height, area, etc. to determine whether the product is qualified, achieving online non-contact measurement without causing any damage to the product and improving production efficiency.

3. Pattern recognition function: online product shape recognition, color recognition to locate the position of objects, as well as QR code recognition and character recognition functions.

4. Robot visual positioning function: used to guide the robot's operations and actions within a wide range, locate and find the position coordinates of objects, guide the positioning of various objects of the robot to operate the motion control of the machine.

来源声明:本文章系english编辑原创或采编整理,如需转载请注明来自english。以上内容部分(包含图片、文字)来源于网络,如有侵权,请及时与本站联系(400-8560-998)。