The Application of Visual Inspection in Various Industries

The production capacity of China's electronic industry accounts for about 70% of the world's total production capacity, making it the largest electronic product manufacturer.

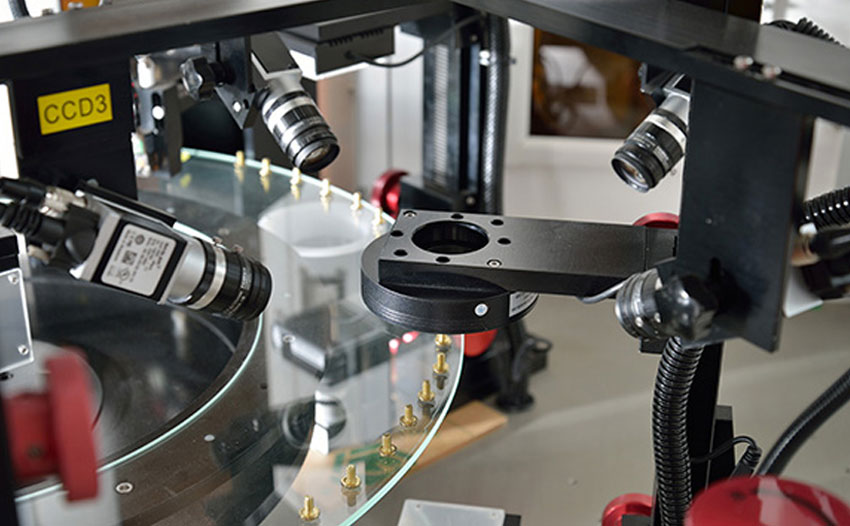

In the electronics industry, the number of visual inspection devices used in each market segment varies. The entire process of mobile phone production requires multiple systems, such as PCB printed circuits, electronic packaging, screen printing, SMT surface packaging, SPI solder paste inspection, and reflow soldering. And wave soldering, semiconductor and integrated circuit manufacturing will use visual inspection equipment.

Consumers of today's consumer electronics devices look forward to seeing flawless products with scratches, unevenness, and other defects that may result in expensive returns, damage brand reputation, and require warranty. Even worse, these defects will have a certain degree of impact on your brand reputation and future business development.

Quality control operations for preventing and detecting surface defects typically rely on manual inspectors. As production speed becomes faster, products become more complex, or product defects become more obscure, manual inspection becomes more difficult to achieve the same quality standards while meeting production efficiency. Requirements. The machine vision inspection system works faster and has higher accuracy, which can greatly avoid the drawbacks and drawbacks of manual inspection and generate better benefits.

3. Application in the automotive manufacturing industry

The production capacity of China's electronic industry accounts for about 70% of the world's total production capacity, making it the largest electronic product manufacturer.

In the electronics industry, the number of visual inspection devices used in each market segment varies. The entire process of mobile phone production requires multiple systems, such as PCB printed circuits, electronic packaging, screen printing, SMT surface packaging, SPI solder paste inspection, and reflow soldering. And wave soldering, semiconductor and integrated circuit manufacturing will use visual inspection equipment.

Consumers of today's consumer electronics devices look forward to seeing flawless products with scratches, unevenness, and other defects that may result in expensive returns, damage brand reputation, and require warranty. Even worse, these defects will have a certain degree of impact on your brand reputation and future business development.

Quality control operations for preventing and detecting surface defects typically rely on manual inspectors. As production speed becomes faster, products become more complex, or product defects become more obscure, manual inspection becomes more difficult to achieve the same quality standards while meeting production efficiency. Requirements. The machine vision inspection system works faster and has higher accuracy, which can greatly avoid the drawbacks and drawbacks of manual inspection and generate better benefits.

3. Application in the automotive manufacturing industry

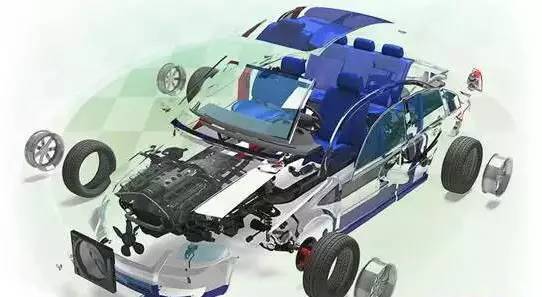

A car is composed of thousands of parts. For cars, the quality of every component, from the engine to the screws, plays a crucial role. Therefore, the quality management of automotive components should become the focus of management for large automotive enterprises.

Through machine vision inspection equipment and modern inspection technology, it is possible to accurately and quickly inspect and diagnose the working condition of automobiles, determine the degree of use of automobiles, and timely maintain and repair automobiles to ensure their integrity and service life, improve transportation efficiency and production efficiency, and reduce the risk of traffic accidents caused by vehicle malfunctions.

In this era of technological development, the use of visual inspection equipment to inspect products is a common phenomenon. More and more manufacturers are using visual inspection equipment to strengthen their product quality management. I believe that in the future development, the application range of visual inspection will become increasingly widespread.

来源声明:本文章系english编辑原创或采编整理,如需转载请注明来自english。以上内容部分(包含图片、文字)来源于网络,如有侵权,请及时与本站联系(400-8560-998)。