What are the factors that affect the effectiveness of testing equipment?

1、 Hardware selection

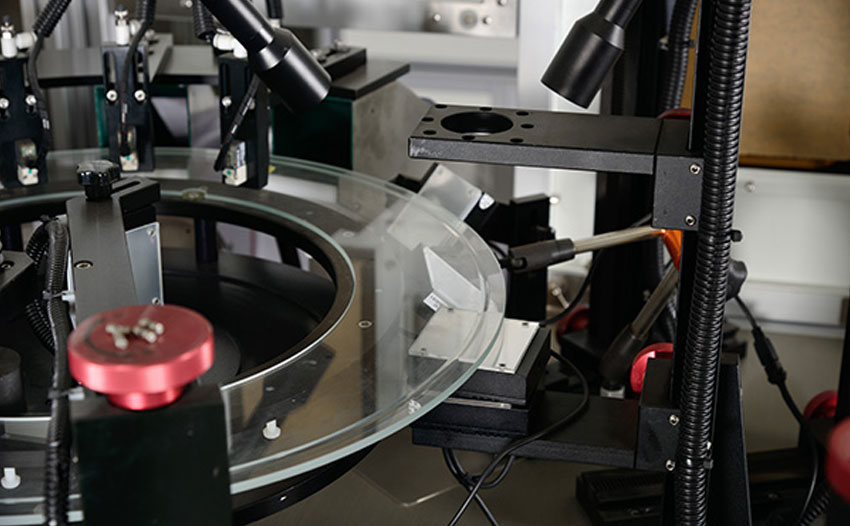

Stable image feature extraction is a prerequisite for image analysis and recognition, ensuring a stable image transmission to the image processing center to ensure the accuracy of software image processing. Many factors can affect the stability of imaging, such as the surrounding environment, changes in objects, and the impact of visual hardware.

The selection of hardware for visual inspection is a challenging task, as it requires engineers to be very familiar with the hardware itself and the hardware supplier, and have sufficient selection experience. The machine vision system running in the laboratory and the system running in actual work scenarios face vastly different environments.

Machine vision inspection equipment defect detection equipment screening machine

Visual inspection includes important components such as light sources, lenses, cameras, image acquisition cards, data transmission, image processing, and measurement software. As the performance of various components improves, the ability of machine vision systems also increases exponentially. The complexity of the system depends on specific application requirements. Choosing the best component not only depends on whether the performance of the component can meet the requirements (such as resolution, frame rate, measurement algorithm, etc.), but also on the environmental conditions in which the system is ultimately located. For example, in the industrial field, these environmental conditions include component changes, load transfer, positioning, processing interfaces, vibration, ambient light, temperature, dust, oil, water, electromagnetic radiation, etc. In extremely harsh conditions, it is sometimes necessary to add protective measures to machine vision components. The most typical example is that some cameras need to be used in relatively clean environments. However, in general, industrial environments can meet the direct use of industrial cameras.

Even the most stable visual system often has unsatisfactory results due to external influences. For example, vibration can cause image blurring and distortion, while variable parts can result in different images. Long exposure times can lead to distortion of the image sharpness of moving objects.

2、 Environmental impact

The impact of the environment on machine vision hardware not only refers to the destructive nature of the hardware itself, but also has an impact on measurement results. For example, in environments with temperature changes, most industrial cameras can operate between -5 degrees and 65 degrees. In practical environments, excessively high temperatures often bring noise to the camera's imaging. However, this can be achieved by improving the lighting method to improve the signal-to-noise ratio.

In addition, temperature can affect the performance of LED light sources. As the LED temperature increases, its brightness decreases, which can be compensated for by the light source controller for brightness output. The heat generated by LED itself can also accelerate aging and even directly scrap, so a good thermal design is necessary.

Other components also have corresponding temperature limits, such as industrial controllers/embedded PCs that can generally be used in industrial environments, but without fans, it is likely that PCs will also be scrapped. In order to ensure the stability of visual imaging, in addition to selecting good hardware, we also need to consider the sensitivity of the tested object to temperature. For example, metal objects have thermal expansion and contraction to temperature, so when measuring such objects, both length and volume will change.

vibration

Most industrial cameras are equipped with anti vibration treatment, and robots and track cables can effectively prevent camera movement from being affected by vibration. The locked connector can prevent the camera from being subjected to vibration. Durable PCs and embedded computers have excellent stability protection mechanisms. The fixed focus lens utilizes metal interface locking screws to ensure it is not affected by vibration. The filter protects the lens to a certain extent.

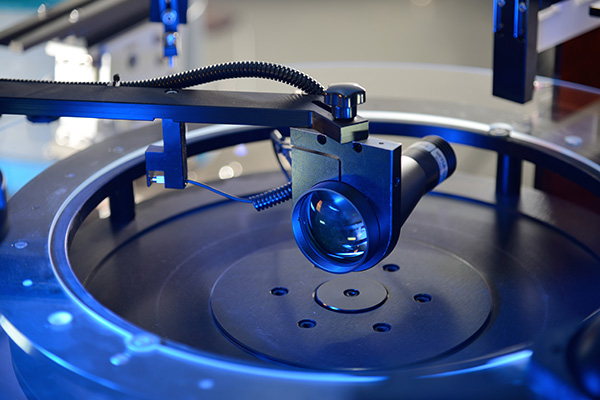

Ambient light

Daily use filters can to some extent avoid being affected by ambient light, as they can alter the information that light enters the sensor. By using a high brightness modulated light source, reducing sensor exposure time and aperture, the impact of ambient light can be minimized. Using infrared and other wavelength cameras for measurement can reduce the impact of visible light.

Dust, dirt, water

Many cameras can achieve IP65/67 protection level, ensuring dust and water resistance. Dust, dirt, liquids, and vapors often adhere to the surface of LEDs or lenses, affecting imaging. Adjustments can be made by increasing the gain of the camera, software image processing, and adjusting the output of the LED.

Various environmental factors can have an impact on imaging, and these effects can be fatal because images are an important reference for measurement.

来源声明:本文章系english编辑原创或采编整理,如需转载请注明来自english。以上内容部分(包含图片、文字)来源于网络,如有侵权,请及时与本站联系(400-8560-998)。