The Role of Visual Inspection in the Future of Intelligent Manufacturing in Industry 4.0

1. The development status and trend of visual robots in China

Robot technology is an important component of high-tech. Its industrialization process has only just begun in our country. Despite some achievements, there are still many difficulties and shortcomings. Therefore, it requires multiple aspects of attention and support. National policy support is an important prerequisite for accelerating the industrialization of high-tech. The relevant departments of the Chinese government should organize efforts to conduct sufficient investigation and research, and on this basis, formulate practical and feasible policies to promote the application and research of robots. For example, implementing support policies for the robotics industry in terms of taxation, investment, and loans.

Machine vision is a thematic technology widely used in industrial fields such as manufacturing inspections to ensure product quality, control production processes, and perceive the environment. The machine vision system converts the captured target into an image signal and transmits it to a dedicated image processing system. Convert pixel distribution, brightness, color, and other information into digital signals. The image system performs various operations on these signals to extract the features of the target, Then control the action of on-site equipment based on the discrimination results.

2. Typical Applications of Machine Vision Technology in the Automation Industry

Nowadays, automation technology is rapidly developing in China. People have gained a deeper understanding of machine vision, and their views on machine vision have also undergone significant changes. The machine vision system has improved the level of automation in production, making it possible for hazardous working environments that are not suitable for manual operation, making mass production and continuous production a reality, and greatly improving production efficiency and product accuracy. The ability to quickly obtain and automatically process information also facilitates information integration in industrial production. With the maturity and development of machine vision technology, it is not difficult to find that its application range is becoming wider and wider. Based on these fields, we can roughly summarize the five typical applications of machine vision. These five typical applications can also fundamentally summarize the application of machine vision technology. The role that can be played in industrial production.

1. Image recognition applications

Image recognition is the use of machine vision to process, analyze, and understand images, and recognize targets and objects in various patterns. The most typical application of image recognition in the machine vision industry is the recognition of two-dimensional codes. QR code is the most common type of barcode we usually use. Store a large amount of data information in this small two-dimensional code and track and manage products through barcodes. Through the machine vision system, it is easy to identify and read barcodes on the surface of various materials, greatly improving the efficiency of modern production.

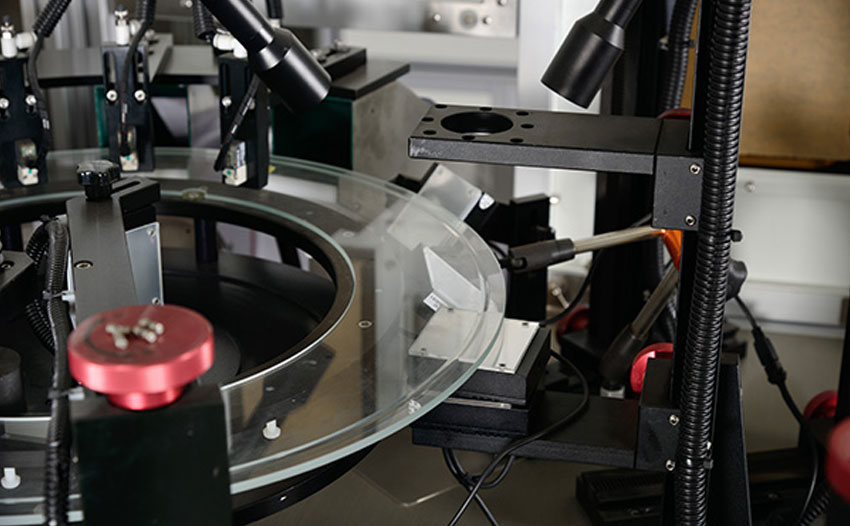

2. Image inspection application

Inspection is one of the most important applications in the machine vision industry. Almost all products require inspection. Manual inspection has many drawbacks. The accuracy of manual inspection is low. If you work long hours, accuracy cannot be guaranteed. Slow speed can easily affect the efficiency of the entire production process. Therefore, machine vision is also widely used in image detection, such as detecting characters on the edges of coins. In the fifth set of RMB issued in October 2000, the side of the one yuan coin had enhanced anti-counterfeiting function. Given the strict control requirements of the production process, a visual inspection system was installed during the final process of coinage. In addition, it can also be used for color registration and color comparison inspection during the printing process, printing quality inspection of beverage bottle caps during the packaging process, barcode and character recognition on product packaging, and defect detection of glass bottles. Among them, detecting defects in glass bottles through machine vision systems also includes the category of medicinal glass bottles. That is to say, machine vision also involves medicine, mainly including size inspection, bottle appearance defect inspection, bottle shoulder defect inspection, bottle mouth inspection, etc.

3. Visual positioning applications

Visual positioning requires a machine vision system to quickly and accurately locate the tested part and confirm its position. In the field of semiconductor packaging, devices need to adjust the pickup head based on the chip position information obtained through machine vision, accurately pick up the chip and bind it. This is the most basic application of visual positioning in the machine vision industry.

4. Application of object measurement

The biggest feature of machine vision industrial applications is its non-contact measurement technology, which also has high accuracy and high-speed performance. However, non-contact and wear free measurement eliminates the hidden danger of secondary damage caused by contact. Common measurement applications include gear, connector, automotive parts, IC component pins, Fried Dough Twists drill and rolling thread testing.

5. Object classification application

In fact, the application of object classification is based on the recognition and detection of links, and images are processed through machine vision systems to achieve classification. In machine vision industrial applications, it is commonly used for food classification, automatic classification of surface defects on parts, and cotton fiber classification.

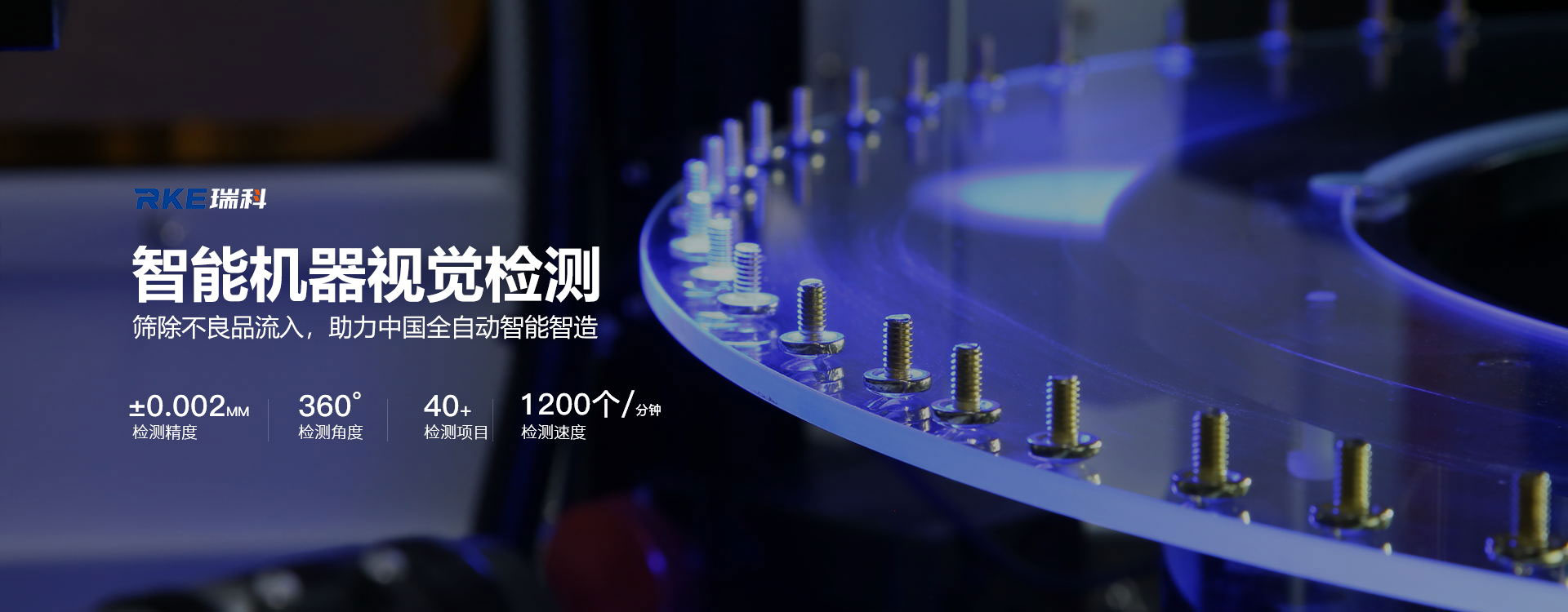

Summary: Ruike Intelligence has also been deeply rooted in the field of industrial grade machine vision for many years, and has developed leading domestic technologies such as industrial robot 3D visual guidance system and 2D positioning.

来源声明:本文章系english编辑原创或采编整理,如需转载请注明来自english。以上内容部分(包含图片、文字)来源于网络,如有侵权,请及时与本站联系(400-8560-998)。