Can optical detection screening equipment detect multiple products simultaneously?

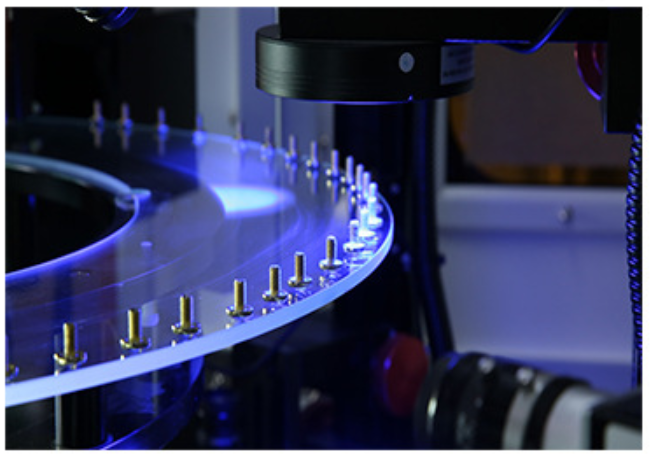

The program, software, and configuration of a device have been set up, such as testing sealing rings. The customer requires testing for appearance, size, diameter, etc. Similar models of products can be tested. However, if the customer needs to test large sealing rings, the testing requirements and content are more, and this device cannot meet this requirement.

In fact, many processing factories have already completed the transformation and development towards automation technology, applying new machine vision technology to carry out IQC on the surface of product appearance. It can replace traditional manual quality inspection and complete efficient automated technical inspection of product appearance online. According to the ability of this machine and equipment to independently perform and complete automatic retrieval of product surface defects, the inspection rate can achieve the same level as the automatic production line. The appearance of the products produced and manufactured by the company is one of the most important factors for product quality. Whether they are leveled and free from defects not only affects the sensory enjoyment of the product, but also affects its own application and post production processing.

Introduction to visual defect detection equipment:

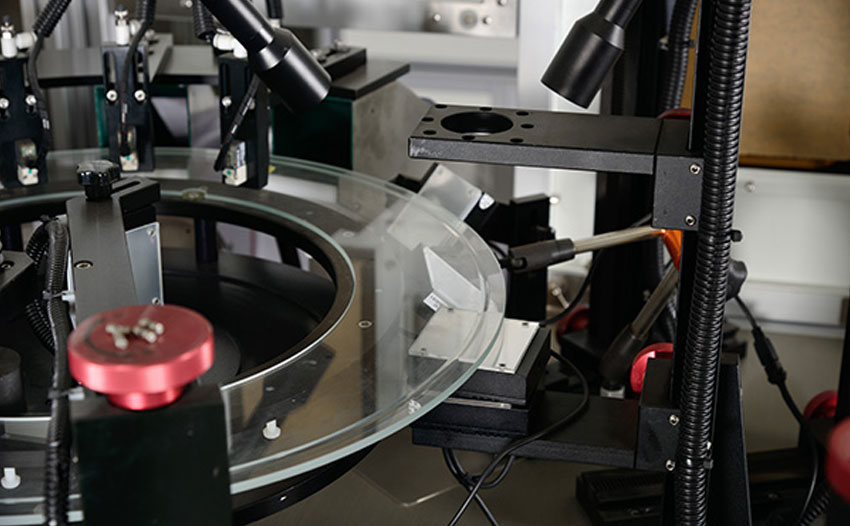

When light shines on the surface of a product with various defects, various defects will exhibit anomalies that are different from the surrounding areas at the reflective surface, mapping, and other levels. For example, when uniform light shines vertically on the surface of a product, if there are no defects on the surface, the irradiated area is not easily changed, and the detected light is also uniform; When there are defects on the surface of the product, the light emitted will change, and the detected image will also change accordingly.

Due to the presence of defects, stress and deformation occur around them, which is also very easy to observe in the image. If encountering light scattering defects (such as cracks, bubbles, etc.), light will generate a mapping at the defect location, and the intensity of the light is greater than that of the surrounding area. Therefore, the light detected on the surface of the camera target is relatively higher; If light absorbing residues (such as sand particles) are encountered, the light at the defect area will weaken, and the light detected on the camera target surface will be weaker than the surrounding light. The analysis of appearance defect detection instruments can obtain relative defect information content by analyzing the high and low transitions and image characteristics of the image data signals collected by the camera.

Visual defect detection equipment Machine equipment characteristics:

1. Complete partial full inspection at maximum efficiency; 2. Digital cameras and technical solutions can quickly detect, classify, display information, and remove defects; 3. High quality electronic optical configurations are used for inspection of urgent defects, even low saturation defects; 4. Intelligent classification of mobile software: Defects are based on being accurately classified into each file directory; 5. The actual operation is simple and convenient, and the defect monitoring system can be implemented without the need for further learning; 6. The information content is accurate, real-time, and reliable.

Visual defect detection equipment can not only detect the appearance size of products, but also detect assembly lines, achieve label and barcode detection, etc.

Ruike Intelligent Technology Co., Ltd. focuses on the research and production of visual inspection equipment. Welcome to inquire and learn more about inspection cases and videos.

来源声明:本文章系english编辑原创或采编整理,如需转载请注明来自english。以上内容部分(包含图片、文字)来源于网络,如有侵权,请及时与本站联系(400-8560-998)。