Intelligent Manufacturing Future Ruike Intelligent Machine Vision Assists New Development of Automated Testing

With the rapid development of domestic manufacturing industry, the requirements for product inspection and quality continue to increase. The industrial automation demand for image and machine vision technology in various industries will be increasing. Therefore, machine vision will have great development space in the future manufacturing industry.

Driven by artificial intelligence technology, Ruike Intelligence, one of the representative technology enterprises in machine vision, plays a crucial role in the field of automated testing.

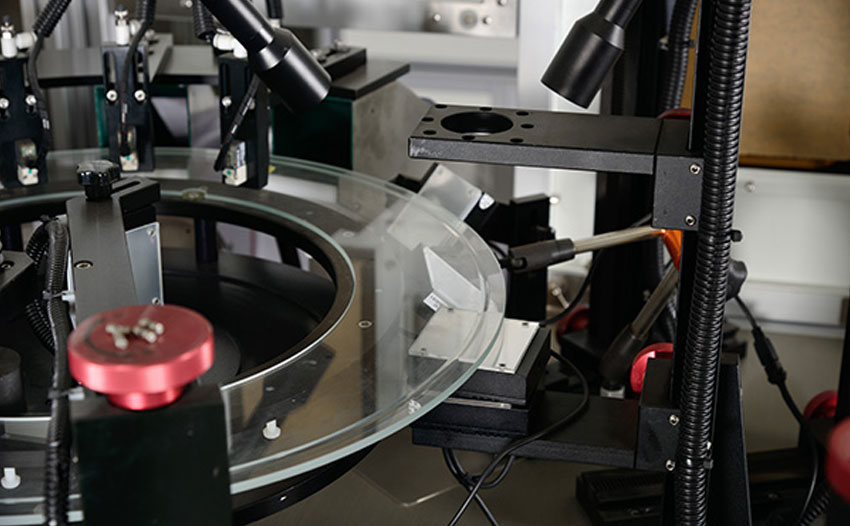

Technological innovation has led to the widespread application of Ruike Intelligent Machine Vision in industries such as electronics, automobiles, metallurgy, food and beverage, spare parts assembly, and manufacturing. It can improve the production capacity of qualified products and scrap inferior products early in the production process, thereby reducing waste and saving costs. This feature is very suitable for imaging product attributes such as height, shape, quantity, and even color.

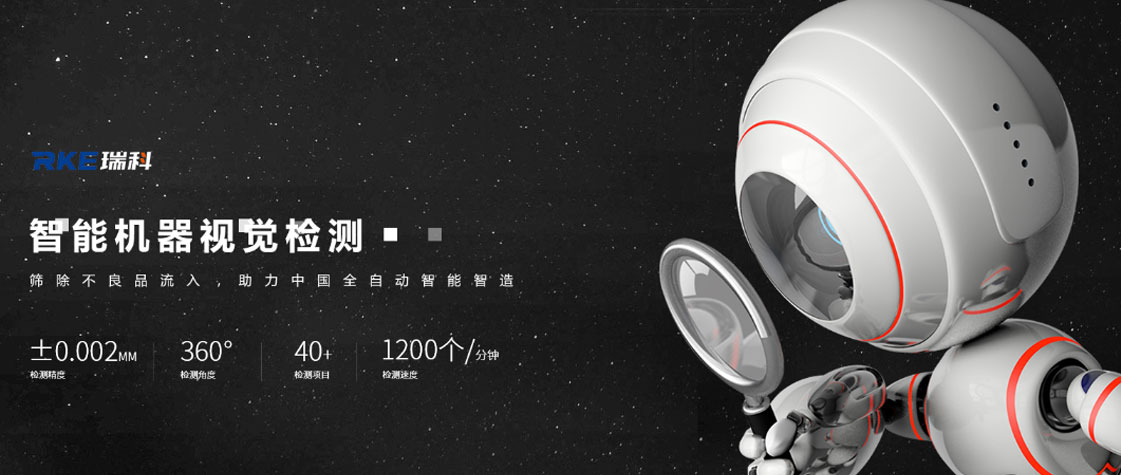

Ruike Intelligent Machine Vision Strives into a New Future of Automated Testing Equipment. Ruike Intelligent, with its technological strength and high-quality testing products, has demonstrated the confidence and strength of Chinese intelligent manufacturing brands to countries around the world, and has also been widely praised by customers in China and even the world. In the field of automotive fasteners, Ruike Automation has always been a long-term and stable mutually beneficial partner for manufacturers such as BYD, Taizhou Gongjiao Machinery, 7412 Factory, Qiangneng Power, and Changhua Company.

In the hardware manufacturing and consumer electronics industries, Ruike Automation enjoys a high reputation and has always been an excellent supplier of famous brands such as Samsung, Foxconn, Green Dot Group, Midea, Yingfeng Holdings, Lingsheng, Beijing Jingtie, Cunjin Group, and Zhongjing Group.

As a high-tech enterprise specializing in the production of optical vision (non-contact) automated testing equipment, Ruike Intelligent always raises the banner of "China Intelligent Manufacturing" and has obtained national patents multiple times. Ruike has applied for dozens of application patents, invention patents, and visual software patents; Also awarded the certificate of key promotion unit for "Famous Chinese Brands" and the title of "Top Ten Equipment Brands" for Chinese fasteners in 2013; Multiple technologies are at the forefront of this field... Ruike Intelligence has become a microcosm of China's gradually leading global development industry, contributing to the global rise of Chinese manufacturing.

With the arrival of 5G and AI intelligence, China's intelligent manufacturing has embarked on a new round of transformation. There is reason to firmly believe that Ruike Intelligence will rely on its own professional testing capabilities to continuously improve product quality, gain global recognition for Made in China, and add luster to Chinese brands.

来源声明:本文章系english编辑原创或采编整理,如需转载请注明来自english。以上内容部分(包含图片、文字)来源于网络,如有侵权,请及时与本站联系(400-8560-998)。